Dawn in the Vertical City

The world outside the Infarmight facility is just beginning to stir, but inside, the work has been continuous. The massive, multi-story structure, nestled discreetly within the urban landscape, is a silent testament to the future of food. It doesn’t rely on the sun’s schedule or the whims of the weather; its rhythm is governed by the precise, unwavering logic of its central intelligence, which we call Aura.

As the clock ticks past 5:00 AM, the facility’s internal lighting system begins its programmed transition. Instead of a sudden, jarring switch, the high-efficiency LED panels shift their spectrum, mimicking the gentle rise of a natural sun. This is not for human comfort, but for the crops, which respond to specific light wavelengths at different stages of their growth cycle. The air is a constant, gentle hum—the sound of filtered, perfectly conditioned air circulating through the racks, ensuring every leaf receives its optimal share of CO2.

Aura, the AI farm manager, has been awake all night, processing terabytes of data. It is a 24/7 operation where every millisecond is logged, analyzed, and acted upon. The system is a closed loop of biological and digital feedback, ensuring peak performance.

The Morning Report: Aura’s Analysis

The first major task of the day is the “Morning Synthesis Report.” Aura doesn’t just monitor; it predicts. Using machine learning models trained on years of growth data, it runs simulations to identify potential stress points hours before they manifest physically.

At 6:00 AM, the report is finalized. It’s a comprehensive dashboard that highlights any deviation from the ideal growth curve. For instance, in Rack 4, Level 7, a slight increase in the leaf surface temperature of the butterhead lettuce was detected overnight. Aura has already responded by marginally increasing the air flow in that specific micro-zone and adjusting the nutrient delivery schedule to compensate for the increased transpiration rate.

The core of Aura’s work is precision agriculture taken to an extreme. It manages the Nutrient Film Technique (NFT) system, a closed-loop network that delivers a perfectly balanced, pH-adjusted mineral solution directly to the roots of the plants. The system uses 95% less water than traditional field farming, with zero runoff.

Here is a snapshot of the environmental parameters Aura is currently maintaining for a batch of high-yield kale:

| Parameter | Target Value | Current Reading | Aura’s Action |

|---|---|---|---|

| Air Temperature | 21.5°C | 21.5°C | Maintain |

| Relative Humidity | 65% | 64.8% | Slight misting increase |

| CO2 Concentration | 1200 ppm | 1205 ppm | Maintain |

| Nutrient pH | 6.0 | 6.02 | Minor acid injection |

| Light Spectrum | 660nm (Red) / 450nm (Blue) | Optimal | Maintain |

The Human Touch: The Agronomist’s Walkthrough

While Aura handles the minute-by-minute operations, the human team provides the critical layer of validation and strategic oversight. Dr. Lena, Infarmight’s lead agronomist, arrives at 7:30 AM. Her day is not spent tilling soil or hauling water; it is spent interpreting data and conducting physical inspections.

Dr. Lena reviews Aura’s report, focusing on the flagged anomalies. She heads to Rack 4, Level 7. The AI’s thermal imaging flagged a potential issue, but Dr. Lena’s experienced eye is the final arbiter. She uses a handheld multispectral scanner to confirm the AI’s diagnosis. The slight temperature increase was indeed due to a minor blockage in a single NFT channel, causing a localized rise in root temperature. Aura’s preemptive adjustment was correct, but Dr. Lena manually clears the blockage, ensuring the system returns to perfect equilibrium.

This partnership between human expertise and artificial intelligence is the heart of Infarmight’s success. The AI handles the scale and complexity; the human provides the intuition and final quality control.

The Nutrient Symphony: Precision Feeding

The mid-morning is dedicated to the nutrient reservoir. This is where the “soil” of the vertical farm resides—a carefully calibrated, sterile, and constantly monitored water solution.

Infarmight’s nutrient solution is a proprietary blend, customized for each crop variety. For their signature “Urban Mint,” the solution is rich in specific micronutrients that enhance the essential oils, resulting in a more potent flavor profile than its field-grown counterpart. Aura manages the dosing pumps with sub-milliliter precision, ensuring the Electrical Conductivity (EC) and pH are always within a tight tolerance band.

The system is a model of resource efficiency. Water that is not absorbed by the plants is collected, sterilized, re-oxygenated, and remixed with fresh nutrients. This closed-loop system means that every drop of water is used multiple times, drastically reducing the farm’s environmental footprint. The only water lost is through plant transpiration, which is then managed by the dehumidification system.

Harvesting the Future: Efficiency in Motion

By noon, the harvest is underway. This is where the farm’s design truly shines. A batch of Infarmight’s premium red-leaf lettuce, planted exactly 35 days ago, has reached its pre-determined peak maturity.

The harvesting process is almost entirely automated. Robotic arms, guided by computer vision, gently lift the mature plants from the racks. The system is designed to minimize handling and stress on the produce. The plants are immediately transferred to a sterile processing area where they are packaged, often with the roots still attached, to maximize shelf life and freshness.

This “living produce” model is a key differentiator. Because the farm is located in the city, the time from harvest to delivery is measured in hours, not days. This “zero-mile” food system ensures that consumers receive produce at its absolute nutritional and flavor peak.

Beyond the Walls: Sustainability and Community

The afternoon shifts focus from internal operations to external impact. Infarmight is not just a farm; it’s a piece of urban infrastructure designed for sustainability.

The facility is powered by a combination of grid energy and a significant array of rooftop solar panels. While vertical farming is energy-intensive due to the LED lighting, Infarmight has invested heavily in the latest generation of energy-efficient lights and a smart energy management system that shifts non-critical operations (like water sterilization) to off-peak hours. The heat generated by the LEDs is captured and often used to heat the adjacent office spaces or is fed into a district heating network, turning a waste product into a resource.

Furthermore, Infarmight actively engages with the local community. Every Tuesday and Thursday afternoon, the facility hosts educational tours for local schools and community groups. It’s a chance to demystify modern agriculture and show people where their food comes from—a critical step in building a resilient, food-secure future.

Preparing for Tomorrow: Seeding and Data Feedback Loop

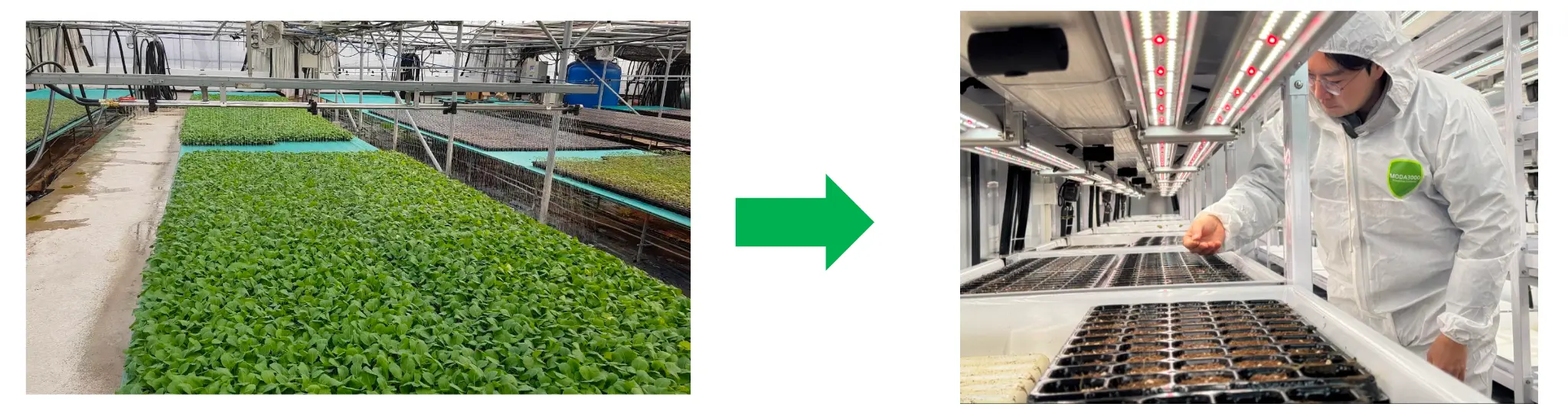

As the day winds down for the human staff, the cycle of growth continues. In the nursery section, a team is preparing the next batch of seedlings. Tiny seeds are placed into sterile growth media, ready to be transferred to the main racks.

Crucially, the data from today’s harvest is immediately fed back into Aura’s machine learning models. Every piece of information—the exact weight of the harvested lettuce, its color saturation, its sugar content (Brix level), and the precise environmental conditions it experienced—is used to refine the growth recipes.

This is the concept of “digital twin” farming. Aura constantly runs thousands of virtual simulations, testing minute changes in light intensity or nutrient ratios in a digital replica of the farm. The best-performing virtual recipes are then deployed to the physical farm, ensuring continuous, incremental improvement in yield and quality. This iterative process is what guarantees Infarmight’s competitive edge.

Sunset and the Promise of Growth

By 8:00 PM, the facility is quiet again. Dr. Lena and the team have gone home, but Aura remains. The AI is now running its nightly diagnostics, monitoring the deep-cycle nutrient replenishment, and ensuring the LED light spectrum is optimized for the plants’ dark period, which is essential for metabolic processes.

The Infarmight farm is a beacon of agricultural innovation. It is a place where technology and nature work in perfect synchrony, producing fresh, nutritious food with minimal environmental impact. The day is over, but the growth never stops. Every hum, every flicker of light, and every drop of water is a promise of a more sustainable, food-secure tomorrow, cultivated right in the heart of the city. The future of farming is here, and it is bright, precise, and always on.

Leave a Reply